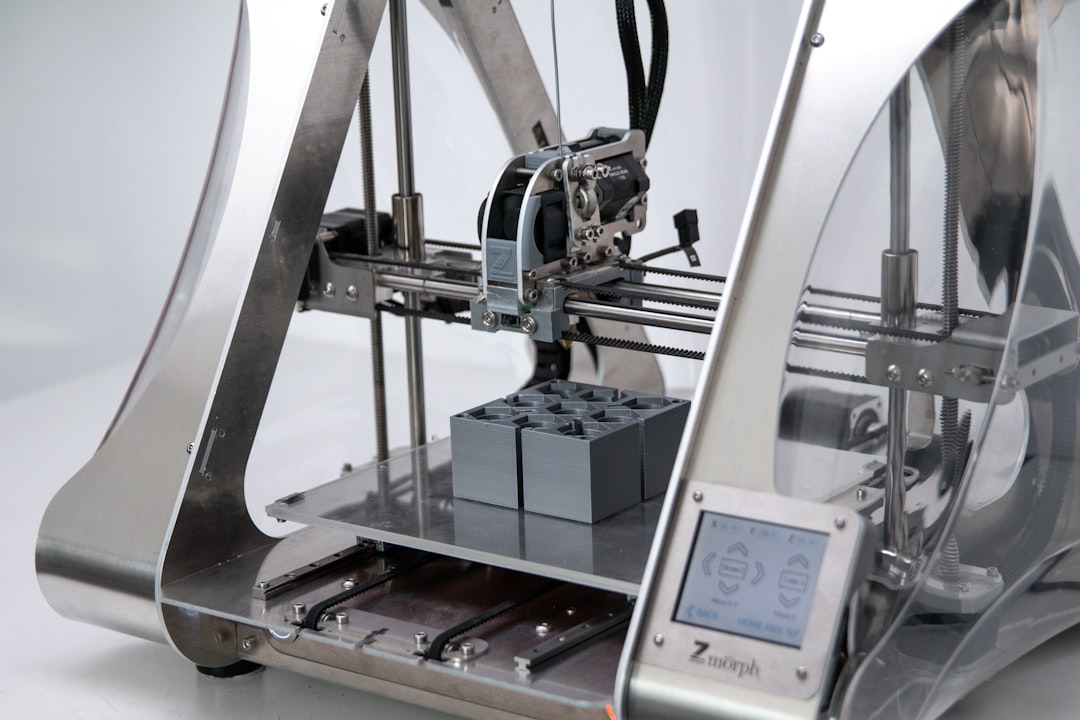

OEM parts electronic production is a new production technique that enables a part to be made with additive production, or 3D printing. This is a fantastic means to speed up the production of spare components and also bring them to market in a much more eco-friendly and also cost-efficient fashion. Spare parts are a key component to lots of items. Whether it is an automobile, computer, appliance or something else, a supplier needs to replace a part at some point. It is important that these parts be produced in such a way that guarantees top quality and also resilience. In the current model, a lot of producers like to make use of OEMs to provide their spare components. This is because OEMs use a range of benefits to their consumers, consisting of premium components that are created to collaborate with the original equipment they are mounted on. The value of OEMs is not just in their components however also in their design knowledge as well as technical knowledge. Utilizing their services saves designers, MROs and also procurement specialists money and time. When it comes to extra parts, OEMs are able to supply faster turn-around times than brokers or suppliers. This is because OEMs have the ability to identify the right parts and have them produced swiftly and also at an affordable rate. This saves engineers and also purchase workers money and time by ensuring that they have the precise components they need when they need them. It likewise enables them to make adjustments or updates faster as well as much more accurately. One more advantage is that OEMs can give a warranty for their extra parts, so the customer can be certain that they are buying premium products. This can be essential when it pertains to pricey tools that needs to be kept in solution. OEMs likewise have a significant advantage when it comes to manufacturing and supplying components that are complex. They have a vast array of tools as well as processes that allow them to generate parts in a much more effective manner than other firms. They likewise have a solid focus on quality and also consumer satisfaction, permitting them to deliver a product that is built to last. They can additionally help to produce a brand identification that is attractive as well as appealing to clients, which can bring about increased profits and brand name commitment. Additionally, they are able to use a complete range of services, varying from designing, creating and prototyping the parts to delivering them to the end individual. This makes it much easier for customers to get the parts they need when they need them as well as prevent unneeded repair services. These benefits are why OEMs are an important source for many companies and also customers. They help to increase item development programs, range the manufacture of specialized or details parts and also supply item top quality, resilient parts that consumers have actually pertained to trust. OEMs have a big existence in the automobile market, with more than eighty percent of automobiles offered in The United States and Canada being manufactured with an OEM part. This is why it’s so vital to recognize the distinctions in between an OEM and an aftermarket component.